Copal Knee Spacers

EXPERTISE IN SEPTIC REVISION SURGERY

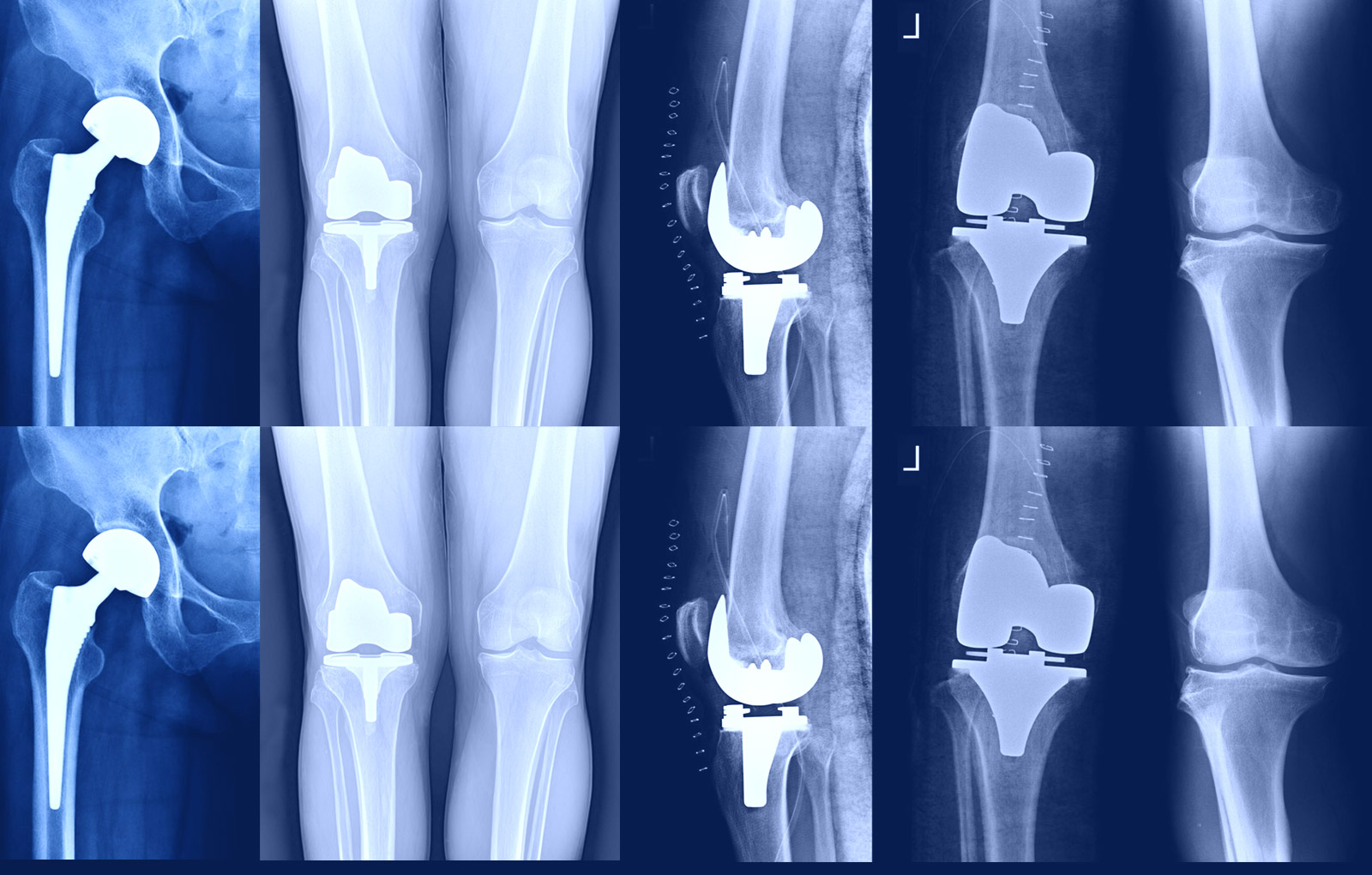

Periprosthetic joint infections are a serious complication in endoprosthetics and present a considerable therapeutic challenge. Two-stage revision has become established as the standard treatment. Spacers made of antibiotic-loaded bone cement provide considerable support for the therapy. Optimal dead space management together with preservation of joint function keeps the patient mobile and accelerates rehabilitation. The revision procedure is made easier and the operation time is shortened.

PREMIUM SPACERS FOR OPTIMAL RESULTS

Spacers prepared with COPAL® knee moulds have an implant-like design with an articulating bearing and high stability. Along with preserving the range of motion, this prevents the formation of contractures and scar tissue. The combination of the design and smooth spacer surfaces reduces the particle wear thus preventing irritation in the adjacent tissue.

IDEAL SPACERS EASILY AND QUICKLY PREPARED

Spacers are easy to prepare using COPAL® knee moulds: Fill the femoral and tibial components, allow the bone cement to cure and then remove any excess cement. Three different spacer sizes with adjustable tibial heights and an optional stem enable preparation of spacers adapted to individual patients and their bone situation. COPAL® knee moulds maintain a stable shape during the filling process and curing of the bone cement. This means that the high quality spacer design can be reproduced.

Advantages at a glance

DESIGN

- For the preparation of implant-like spacers with an articulating surface

- Spacers can be individually adapted to the patient’s bone situation due to the three different mould sizes, height-adjustable tibial components and optional stem

QUALITY

- Quick and easy handling

- Reproducible high quality spacer design due to the shape stability of the COPAL® knee moulds

EXPERTISE

- From the manufacturer of the proven and tested PALACOS® bone cements

- Part of the extensive Heraeus product portfolio for revision and joint arthroplasty

| COPAL® | Description | Content | REF |

| COPAL® knee moulds | Moulds for temporary knee spacers | S M L |

66058094 66058095 66058096 |

| COPAL® G+C | High-viscosity, radiopaque bone cement with gentamicin and clindamycin | 1 x 40 | 66017790 |

| COPAL® G+V | High-viscosity, radiopaque bone cement with gentamicin and vancomycin | 1 x 40 | 66038973 |

| COPAL® spacem | High-viscosity, radiopaque special cement for the manufacture of spacers | 2 x 40 | 66038972 |